Cold Cutting

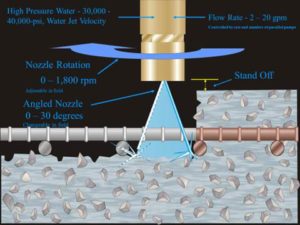

How it works

Dry abrasive is introduced into the 40,000 PSI water stream exiting through an internal orifice and directed against the material being cut. The high energy abrasive/water mixture exits the nozzle as a pressurized stream and impinges the surface cutting the substrate material. The base metal is cut without any heat affected zone.

Learn More

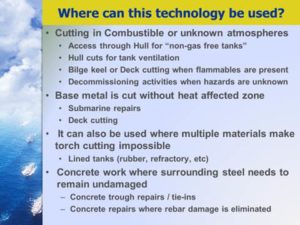

benefits of cold cutting

• No heat affected zone on substrate

• Cold cutting of piping, tanks and doorsheets when hot work is not feasible

• Cutting multiple substrates simultaneously- cuts steel and refractory at the same time

• UHP cutting would eliminate hot work where led paint exists

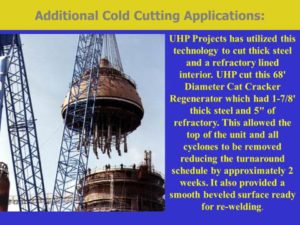

Cat Cracker cutting

HydroPrep has utilized this technology to cut thick steel and a refractory lined interior. UHP water jetting cut this 68′ Diameter Cat Cracker Regenerator which had 1-7/8′ thick steel and 5″ of refractory. This allowed the top of the unit and all cyclones to be removed reducing the turnaround schedule by approximately 2 weeks. It also provided a smooth beveled surface ready for re-welding.

We have built our reputation on the successful completion of projects, advances in equipment, and a proactive involvement with advancing the acceptance of these procedures. One example of these advances was when UHP Projects completed cutting over 6000 linear feet of 1″ steel on the hanger deck of a US Navy aircraft carrier. This project included the containment, cutting, and lead abatement of these areas, which were filled with a combustible preservative, during an active refueling project. This “first of its kind project” was successfully completed on schedule and within budget with an exceptional safety record.

rubber Lined vessels

Because this is a “cold” cut with no heat generated, the technology can be used for many applications. Areas that need heat free zones such as rubber liners (pictured) can be cut with no damage to the liner.

tank applications

The cutting head can be placed on a bevel providing stress free cuts and ready to weld surfaces. Corners can be cut with a radius to eliminate stress and allow doorsheet replacement.

Ready to get started?

Contact Information

HydroPrep

4811 Mercantile Dr., Newport News, VA 23607

Phone: 757-245-3014

Fax: 757-928-1946